Blog

Start Small, Win Big: 4 Food and Beverage Automation Solutions That Boost Plant Uptime

Small sources of downtime—such as slow changeovers, drifting sensors, manual inspection, and unconnected legacy lines—quietly reduce output. This article outlines four practical automation upgrades that any food and beverage plant can implement to quickly regain uptime and demonstrate ROI before scaling.

3 Easy to Install Robotics for Food and Beverage Plants (Fast ROI Certified)

Discover three fast-to-deploy robotics solutions for small food and beverage plants - cobots, palletizing robots, and delta robots - that can deliver labor savings, safer operations, and a certified ROI in as little as 90 days for growing manufacturers.

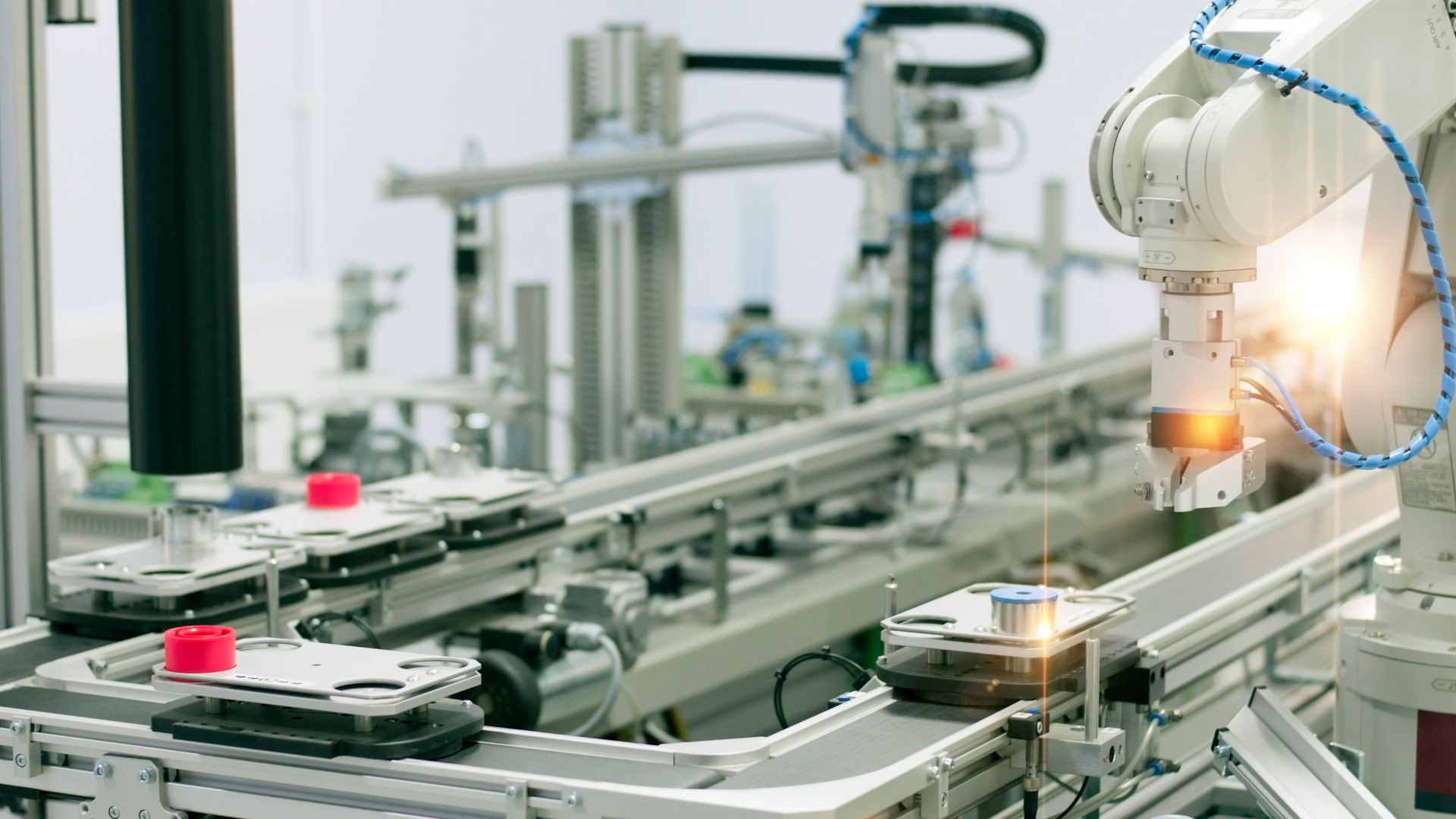

Spark Readiness and Reliability: 5 Robotics Solutions for Defense Plants

Discover five robotics solutions revolutionizing defense manufacturing. From torque-assurance to adaptive kitting, these automation tools enhance readiness, reduce defects, and ensure mission-critical reliability. Learn how leading defense plants are implementing smarter, traceable systems today.

10 Smart Control Fixes to Revive Zombie Teams and Lift Output

Zombie teams drain your plant’s energy and output. Discover 10 smart control fixes powered by human-centric automation to boost morale, reduce shift fatigue, and energize operations—without burning out your people or blowing your budget.

Predict. Prevent. Perform: SCADA and IIoT for Mission Ready Operations

Mission-ready operations demand more than quick fixes. Discover how predictive maintenance, powered by SCADA and IIoT, helps manufacturers prevent costly breakdowns, extend asset life, and maintain critical uptime in high-stakes environments like defense manufacturing.

The Antidote to Erase Clean in Place Process Blind Spots

Clean-in-place process failures aren’t random—they’re predictable and preventable. Discover how modern sensors, smarter PLC logic, and CIP automation eliminate blind spots, stabilize cycles, protect compliance, and cut downtime across food, beverage, and pharma plants while reducing water and chemical waste.

How to Solve Control Loop Failures Before They Crash Your Line

Don’t wait for alarms to scream. Learn how to spot control loop failures early with practical automation know-how—monitoring, diagnostics dashboards, and adaptive PID tuning—to cut downtime, protect yield, and keep your production line stable, compliant, and profitable 24/7.

The Procurement Guide for Smart Automation Success

Buying intelligent automation shouldn’t feel like a gamble. This hands-on procurement guide outlines five essential steps—clarifying specifications, aligning stakeholders, filtering vendors, comparing beyond price, and ensuring safety and compliance—so you can confidently move beyond legacy systems and unlock real ROI.